Product risk assessment and countermeasures

Our engineers can offer customers a complete product risk assessment, in the process of new product development, professional suggestions will be provided for the use of raw materials, molding process, product design and improvement, to ensure the production of high quality products and save time.

Mold design and manufacturing

HONGJINYUAN focuses on tight tolerance components and connectors, special engineering plastics, insert molding, overmolding, multi-material precision mold design and manufacturing. We attach importance to every step in the manufacturing process, from collecting customer insights and needs to mold design project development and discussion, project team members from different departments jointly review customers’ special requirements, and seek to do best.

Precision injection molding

HONGJINYUAN focuses on the injection molding of high-precision parts, multi-material parts, engineering adhesives, and high-gloss appearance parts. We have 30 sets of 80T-318T injection molding machines, Fanuc, Garming, Dayu, to provide customers with large and small volume precision injection molding services.

Special engineering Plastics Molding

In the field of special engineering plastics applications, HONGJINYUAN provides customers with injection molding of high temperature and high precision parts (PEEK, PEI, PPS, LCP and other plastics). Products include auto parts, connectors, transmission parts, high and low temperature resistance, corrosion resistance products, etc.

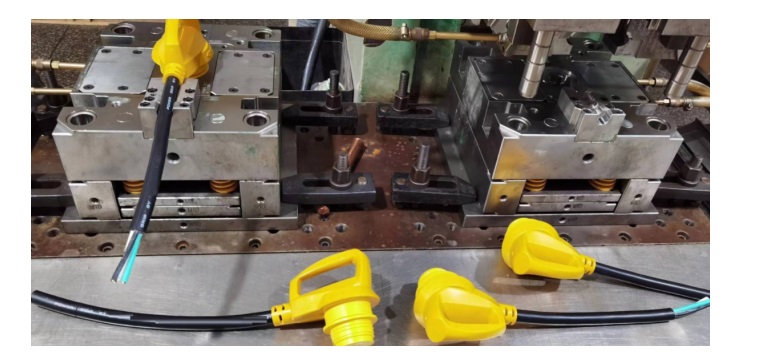

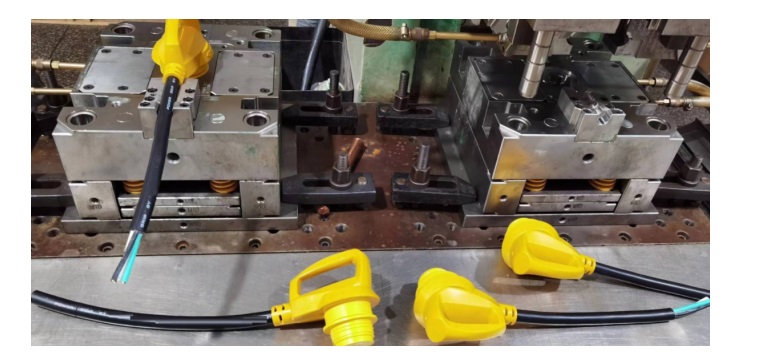

Overmolding

With rich experience in overmolding, HONGJINYUAN can provide customers with medium and small batch of connector cable customization orders on PCB overmolding, low pressure molding PCBA Overmolding, Cable Overmolding and Metals Overmolding. All products are subjected to rigorous quality testing before delivery to meet product requirements and ensure that customers could receive high quality products.

Product risk assessment and countermeasuresOur engineers can offer customers a complete product risk assessment, in the process of new product development, professional suggestions will be provided for the use of raw materials, molding process, product design and improvement, to ensure the production of high quality products and save time.

1  Mold design and manufacturingHONGJINYUAN focuses on tight tolerance components and connectors, special engineering plastics, insert molding, overmolding, multi-material precision mold design and manufacturing. We attach importance to every step in the manufacturing process, from collecting customer insights and needs to mold design project development and discussion, project team members from different departments jointly review customers’ special requirements, and seek to do best.

2 Precision injection moldingHONGJINYUAN focuses on the injection molding of high-precision parts, multi-material parts, engineering adhesives, and high-gloss appearance parts. We have 30 sets of 80T-318T injection molding machines, Fanuc, Garming, Dayu, to provide customers with large and small volume precision injection molding services.

3  Special engineering Plastics MoldingIn the field of special engineering plastics applications, HONGJINYUAN provides customers with injection molding of high temperature and high precision parts (PEEK, PEI, PPS, LCP and other plastics). Products include auto parts, connectors, transmission parts, high and low temperature resistance, corrosion resistance products, etc.

4 OvermoldingWith rich experience in overmolding, HONGJINYUAN can provide customers with medium and small batch of connector cable customization orders on PCB overmolding, low pressure molding PCBA Overmolding, Cable Overmolding and Metals Overmolding. All products are subjected to rigorous quality testing before delivery to meet product requirements and ensure that customers could receive high quality products.

5 |

|